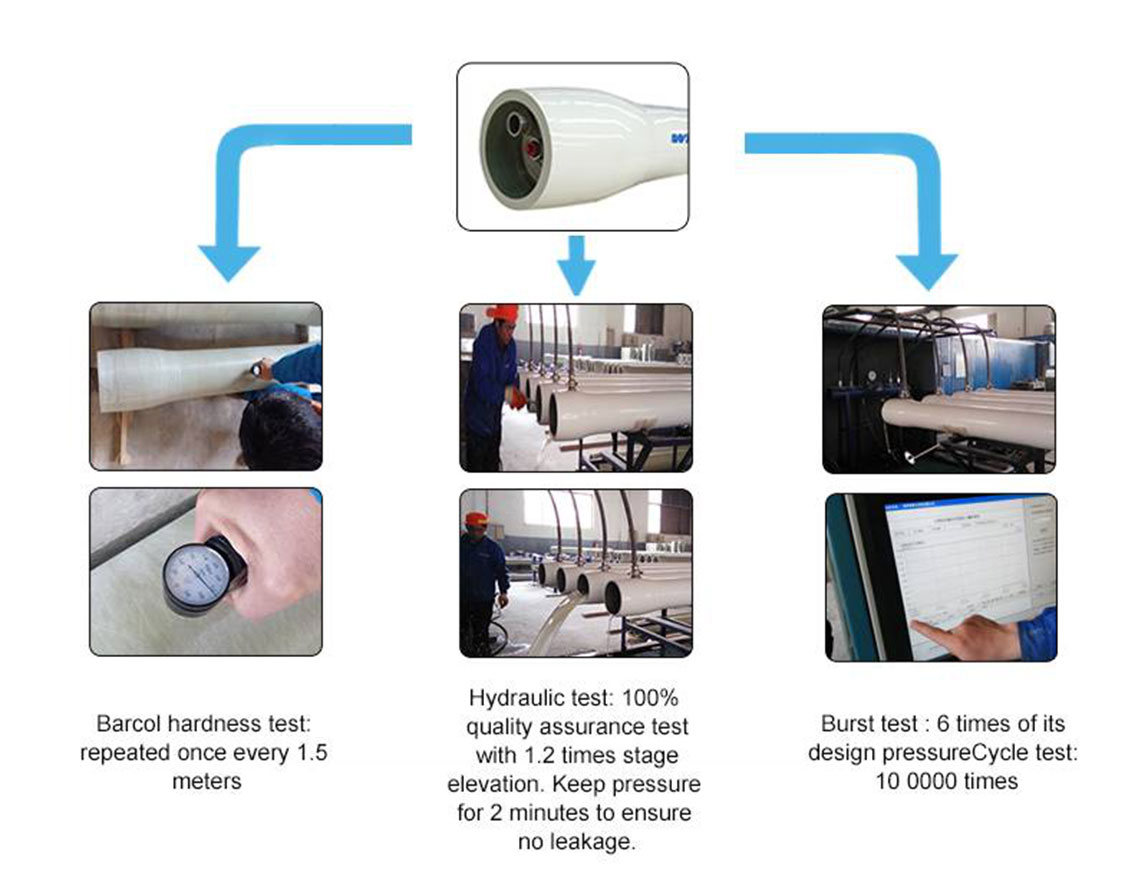

Winder FRP membrane housing pressure vessels burst test, cycle test, hydraulic test, barcol hardness test

Certainly carry out these test procedure, ensure no defective products

Eight Systems for Quality Assurance

1.Supply System

a) After 20 years of precipitation, domestic and foreign suppliers are the three or more annual finalists that Chengda has finalized after a number of field visits, sample inspections, negotiations and evaluations.

b) The shortlisted suppliers will be graded every year, and those who fail will be eliminated. Suppliers with major quality problems will never be included in the list of Chengda group purchasers.

c) Chengda is equipped with a large comprehensive testing center for the testing of raw materials, auxiliary materials, accessories, finished products and the development of new processes.

d) Chengda is equipped with special testing equipment and professional personnel to carry out professional sampling inspection of each batch of raw materials, auxiliary materials and accessories. So as to ensure there are no unqualified.

i.Inspection qualified before storage.

ii.All rejected products will be returned, not allowed to enter the storage and production areas.

If major quality problems and accidents caused by unqualified raw materials are found in the production process, the supplier shall be investigated for responsibility. And the supplier shall never be included in the procurement list of Chengda.

2.Key Parameter Production Process Control System

a)We strictly implement 6S production site improve system originated from Japan.

b)Product quality control testing is divided into two systems

Hydrostatic test shall be done for each FRP pressure vessel with 1.1 times of the designed pressure, 100% test, not sampling. The test shall be performed in strict accordance with the requirements of ASME, and keep pressure for 6 minutes to ensure no leakage.

ii.1000 pcs of the same model are a batch, and carry out sampling inspection

1.100, 000 time of fatigue tests shall be done on the same grade FRP pressure vessels.

2.Burst test with 6 times of its design pressure shall be done on the same grade FRP pressure vessels.

a) Have a 10-people quality inspection team to carry out tracking and quality inspection of raw materials, auxiliary materials, accessories and finished products for 24 hours.

b) Each FRP pressure vessel has a unique ID code to make sure it can be traced back to the person in charge of each process (It is also the security code of our company's products).

3.Self-Developed Advanced Automatic Production Line System and Production Process Technology

a) Chengda and Wuhan University of Technology in China have jointly developed a world-leading winding equipment and production process technology to improve the reliability of equipment operation and ensure product stability.

b) Adopting the most advanced pre-embedded process in the world to avoid the damage of the glass fiber layer during the grooving process, thereby ensuring the pressure coefficient of the membrane shell and improving the quality stability of the membrane shell.

c) Self-developed and put into use of automatic manipulator hydro-grinding shaping production line system. So as to improve production efficiency and product performance stability, reduce labor intensity and costs.

d) Self-developed side port molding production line system has high precision performance. And the tolerance is controlled within 1mm, so as to improve production efficiency and product performance stability, reduce labor intensity and costs.

e) Self-developed automatic large-scale coating equipment improve the adhesion of the pressure vessel and coating, as well as the production efficiency.

The above self-developed equipment and process technology ensure product quality and improve product stability, reduce labor intensity and costs. Thus realize the fully automated assembly line operation of the factory to meet the production standards of modern enterprises.

(Due to the confidentiality of the multiple self-developed mechanical equipment and production processes in the workshop, the pictures are not displayed here. We can see these equipment when we visit the workshop, but we are not allowed to take pictures. Please understand.)

4.Warehousing System: ISO 9001.

5.Packaging System: customized according to customer requirements.

6.Quality Control System: Strictly Implement ISO9001 International Quality Management System

a)We own a 10-person quality inspection team, which is responsible for monitoring the quality of raw material suppliers and the quality tracking of each process in the production.

b)Each FRP pressure vessel has a unique ID code to make sure it can be traced back to the person in charge of each process.

c)Winder series FRP pressure vessel strictly implement ASME standards.

7.Inspection System Before Shipment

A 10-person quality inspection team not only carries out quality inspection in the production process, but also makes the final quality inspection before delivery. Qualified products shall be delivered after the qualified certificate is pasted by the supervisor of quality inspection department.

8.After-Sales Service System: one year warranty, life-long maintenance.

TEST AND INSPECTION EQUIPMENT

I.Muffle Furnace and High Precision Balance-for Test of Resin and Fiber Content of RO Housings and FRP Tanks

Each time after fatigue and burst test of products, we calcined a small portion of the test sample, to get the exact content of fiber and resin. This test plays an important role in the quality control, improvement ,innovation of CHENG DA products.

II.Fatigue Test Equipment-for Test of the Service Life of RO Housings and FRP Tanks

At least one determination for every 1000 duplicate vessels, randomly select one sample, and no leakage during the test at water temperature 65℃,with pressure cycled from minimum pressure 0psig to the design pressure and back 100,000 times. The test is to guarantee the stability of the products.

III.Burst Pressure Test Equipment-for Strength Test of RO Housings and FRP Tanks

Qualified by the cyclic pressure tests, the vessel shall be applied with test pressure at a uniform rate to reach 6 times the design pressure in not less than 1min at water temperature 65℃; for FRP tanks, to reach 4 times the design pressure(or pressure not lower than specific design pressure).This test is to ensure the reliability of the quality of the product.