Reverse osmosis flushing is the use of low pressure and large flow of production water or incoming water to flush the membrane element, wash away the pollutants or deposits attached to the surface of the membrane.

1. Flushing velocity:

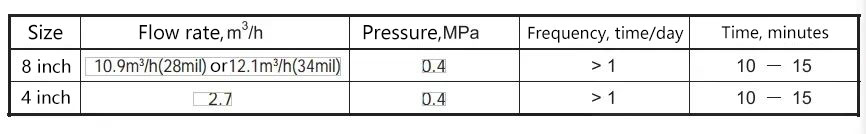

When the device is running, particulate pollutants gradually accumulate on the surface of the membrane. If the flow rate of flushing is equal to or slightly lower than the flow rate of water preparation, it is difficult to flush contaminants out of the membrane element. Use a higher flow rate when flushing than during normal operation. In general, the flushing flow rate in a single pressure vessel is:

8 inch membrane elements: ≤10.9m3/h (28mil) or 12.1 m3/h (34mil) 4 inch membrane elements: ≤ 2.7m3/h

2. Flushing pressure:

Under normal high pressure operation, pollutants are pressed to the surface of the membrane, causing pollution. Therefore, when flushing, if the same high pressure is used, the pollutants will still be pressed on the surface of the membrane, and the cleaning effect will not be ideal.

Therefore, when flushing, the horizontal shear force should be increased as much as possible through the way of low pressure and high flow rate to push the pollutants out of the membrane element. Generally, the inlet water pressure cannot be greater than 0.4 MPa.

3. Frequency of flushing:

It is recommended to flush the system as often as possible. Increasing the number of rinses is more effective than a single chemical wash. The frequency of washing is recommended once a day. According to the specific situation, you can control the frequency of flushing.

Note:

① The inlet water pump needs to meet the inlet water flow during normal operation (inlet water flow = water production flow + concentrated water flow), and must consider meeting the requirements of the flushing flow.

② The choice of concentrated water pipes and valves should also consider the large flow rate during flushing. When making water, the concentrated water flow is relatively small because of the high recovery rate. When flushing operation, it requires low pressure and high flow, and almost all the water is excluded from the concentrated water pipe, so the design of the concentrated water pipe and valve should not only consider the flow when making water, but also consider the flow needs when washing.

If the design of pipes and valves only considers the flow rate at the time of water preparation, the pressure drop at the concentration pipe line and the concentration water valve during flushing may not reach the required flow rate or exceed the flushing required pressure. Of course, you can also consider setting up a special flushing line.

③ The selected flowmeter should take into account the maximum flow rate that can be read when flushing.

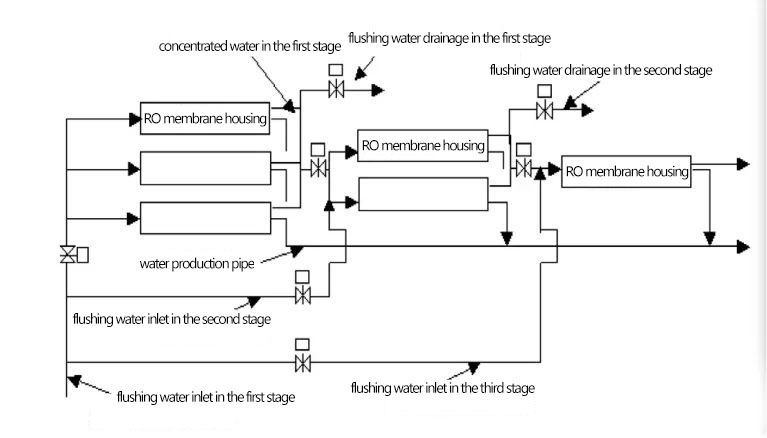

For multi-stage reverse osmosis systems, as shown in the figure below, it is necessary to design the system in such a way that it can be washed in stages in order to be able to wash the membrane elements more effectively.

If the whole section is flushed, the flushing water and pollutants in the first section will flow into the latter section together, which is easy to cause blockage in the latter section.

An increase in the number of stages also means an increase in the number of membrane elements through which the flushing water flows. In order to meet the flow requirements, it is necessary to increase the inlet pressure. The permissible value of the flushing pressure may be exceeded, resulting in an increase in the pressure on the membrane surface, reducing the flushing effect.

When performing the first stage of flushing, fully open the valve of the first stage of flushing concentrated water drainage pipe, close the valve between the first stage of concentrated water and the second stage of inlet, and the second and third stage of inlet flushing valves.

When performing the second stage of flushing, fully open the valve of the second stage of flushing concentrated water drainage pipe, close the inlet flushing valve of the first stage and the third stage, close the valve of the first stage of concentrated water and the second stage of inlet water, close the valve of the second stage of concentrated water and the third stage of inlet water.

When performing the third stage of flushing, fully open the valve of the third stage of flushing concentrated water drainage pipe, close the inlet flushing valve of the first and third stages, and close the valve between the second stage of concentrated water and the third stage of inlet water.