Reverse osmosis membrane pressure vessels feed water sources are divided into groundwater, surface water, sewage treatment plant effluent, etc., the feed water contains various pollutants, the cause of reverse osmosis membrane pollution depends on the pollutants in the water Type, nature and concentration, and the type of reverse osmosis membrane.

For different raw water quality, analyze the types and causes of reverse osmosis membrane housings pollution, and take effective pre-treatment and preventive measures to effectively prevent and delay the pollution of reverse osmosis membranes. In addition, for highly polluted water sources Anti-fouling membranes with wide flow channels, low water supply resistance, and low energy consumption can be used to reduce membrane module pollution and reduce the number of chemical cleanings.

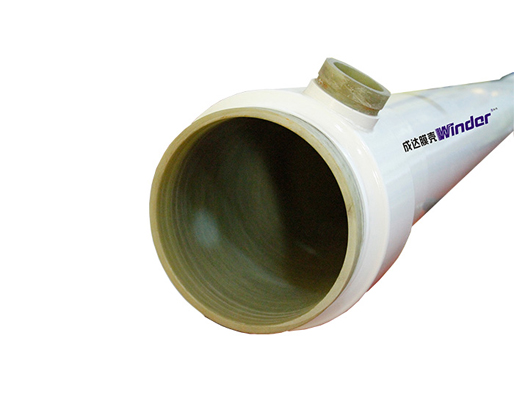

Reverse Osmosis Membrane Pressure Vessels

1.Pretreatment method of raw water

Suspended particles and colloid pollution are mainly caused by the failure of the reverse osmosis feedwater pretreatment system. Therefore, in actual operation, strictly control the reverse osmosis inflow SDI <5 (Using ultrafiltration reverse osmosis inflow SDI <3). Because raw water contains suspended solids or particles, colloids, scaling salts, metal oxides, various microorganisms, organic matter, etc., different pretreatment methods need to be adopted for different influent water qualities to remove them as much as possible.

2.Ion scaling control

Raw water contains a large amount of scale ions such as Ca2 +, Mg2 +, Ba2 +, CO32-, SO42-, etc. In order to prevent the precipitation of CaCO3, CaSO4, BaSO4, etc., to cause the membrane to scale, if the amount of water is relatively large, lime addition or softening method or lime + Soda ash softening method, small amount of water can be solved by adding acid to reduce the pH of the water, or using sodium ions to soften, while adding a specific scale inhibitor.

In order to prevent SiO2 scaling, coagulation sedimentation + filtration process is usually used to reduce the concentration of silica and other water in reverse osmosis, and the feedwater temperature is appropriately increased (when the feedwater temperature is 40 ℃, the solubility of SiO2 can reach 160 mg / L). The method of increasing the pH of the feed water, controlling the recovery rate of the water, and adding a specific scale inhibitor.

When the content of iron and manganese in the water is less than 0.1 mg / L, it may not be treated; when the content of iron and manganese is 0.1 to 0.5 mg / L, the pH of the water can be adjusted to 5.5 by adding acid to prevent the formation of iron and manganese oxides. ; When the content of iron and manganese is greater than 0.5 mg / L, free ions such as iron and manganese in the water are oxidized to form metal oxide deposits to pollute the reverse osmosis membrane. Before the reverse osmosis system, an aeration-manganese sand filtration method is required Its removed.

3. Control of organic pollution and microbial pollution

The method to prevent the growth of microorganisms is to add biocides to the pretreatment of the water. At present, chlorine bactericide is commonly used to control a certain amount of residual chlorine.

If the content of CODMn in the input water is high and biodegradable (such as the effluent from a municipal sewage treatment plant), the method of aerated biological filter + filtration can be used to reduce the input CODMn. In addition, when the content of CODMn with a small amount of water is lower (but higher than the water inlet requirement of the reverse osmosis membrane), an activated carbon filter can also be set in the pretreatment system for adsorption filtration so that the SDI value in the feed water meets the water inlet requirement.

In frp pressure vessels for large RO systems, even if the feedwater SDI meets the reverse osmosis water intake requirement <5 (even when SDI <3), a large number of slimy biofilms may still appear on the membrane surface. It depends on factors such as the type of organic pollutants in the water, the breeding status of bacteria, the temperature of the inlet water and the amount of water flux. The proper pretreatment system is essential to delay the pollution of the reverse osmosis membrane and extend the service life of the reverse osmosis membrane.